Μicroscopy

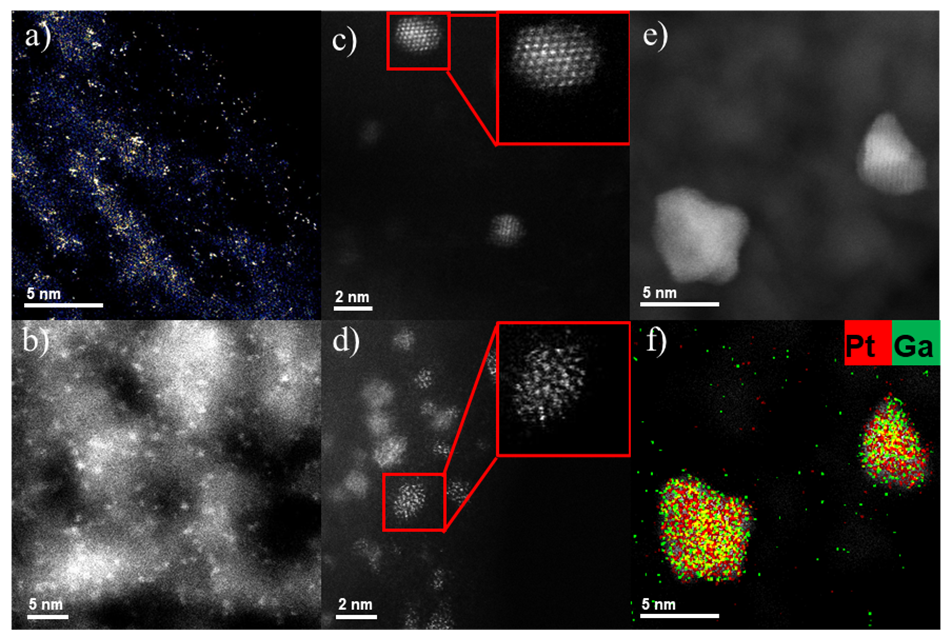

With the development of tailored catalytic materials and our goal to understand reaction mechanisms as well as active sites, we have recently focused on visualizing our model catalysts with atomic scale resolution using state-of-the-art (scanning) transmission electron microscopy ((S)TEM). This technique enables unparalleled imaging capabilities and can be coupled with analytical techniques, such as Energy Dispersive X-ray Spectroscopy (EDS) and Electron Energy Loss Spectroscopy (EELS) for spatially resolved elemental analyses and determination of electronic structure, respectively. Furthermore, high-resolution (S)TEM delivers detailed atomic-scale images, enabling direct visualization of catalysts morphologies, while giving insights into the crystal structure, size, and shape of clusters and nanoparticles, chemical composition, and distribution of small nanoparticles and clusters over the support. Figure 1 showcases a variety of catalytic model systems prepared in our group via a surface organometallic chemistry (SOMC) approach. In contrast to other characterization techniques, high-resolution high-angle annular dark-field STEM (HAADF-STEM) imaging enables direct visualization of highly dispersed grafted Pt species (Figure 1a) and bimetallic PtGa nanoparticles (Figure 1b) on Al2O3. In particular, we show that Pt nanoparticles exhibit highly crystalline ordering on carbon (Figure 1c), whereas the PtGa analogue exhibits amorphous ordering (Figure 1d). These structural differences are further elucidated through spatially resolved elemental analyses. Using STEM-EDS, we observe that PtGa nanoparticles on Al2O3 display complete overlap between Pt and Ga X-ray signals, indicating the formation of alloyed bimetallic nanoparticles (Figures 1e and 1f).These examples underscore the advanced capabilities of HAADF-STEM and STEM-EDS in providing deep insights into the composition and structure of catalytic materials, thereby advancing our understanding of structure-reactivity relationships.

One of the most exciting recent advancements in the TEM field, is the ability to perform in situ and operando studies. These techniques enable the observation of catalytic processes in real-time under realistic conditions. For instance, in situ TEM can capture dynamic changes in catalyst structure and composition during reaction conditions, offering valuable insights into structure-property relationships. Operando TEM extends this capability by enabling the observation of catalysts under actual working conditions, such as high temperatures and gaseous environments, while simultaneously monitoring reaction products. This real-time monitoring is essential for understanding the dynamic interaction of catalysts with reactants, such as the evolution of the active structure on the nanoscale, and for gaining insights into how catalysts deactivate over time. Recently, at ScopeM a state-of-the-art custom-built software for in situ and operando electron microscopy has been implemented. This software solution unifies the control of sample heating, gas dosing and mixing, and mass analyser functions. It continuously stores integrated data in a time-series database, enabling real-time data correlation and visualization using an open source Grafana interface. This comprehensive solution enhances safety and efficiency, while providing a universal overview of experiment parameters, significantly streamlining in situ TEM experiments.

In summary, we are focused on advancing the TEM approach to improve atomic scale characterization and visualization of supported mono- and bimetallic catalytic systems, both ex situ and in situ. Nevertheless, we are facing significant challenges, due to destructive electron beam interactions with our materials, resulting in charging supports, carbon contamination, low signal to background, and electron beam damage. To mitigate these hurdles, we are optimizing experimental conditions and exploring the use of non-charging supports such as carbon. Moreover, we are working on the development of new in situ TEM tools to enable the observation of catalyst dynamics under reaction conditions. Our goal is to improve accuracy and reliability of TEM techniques in studying catalytic processes, which will provide deeper insights into structure-activity relationships, which control the performance of nanoscale catalysts and facilitate the design of more efficient catalytic materials. Our results will be shared in due course.